Econoboard Insulation is recommended for an energy-efficient electric underfloor heating system. A layer of Econoboard will help prevent heat loss into the substrate and ensure faster heat-up times for the underfloor heating.

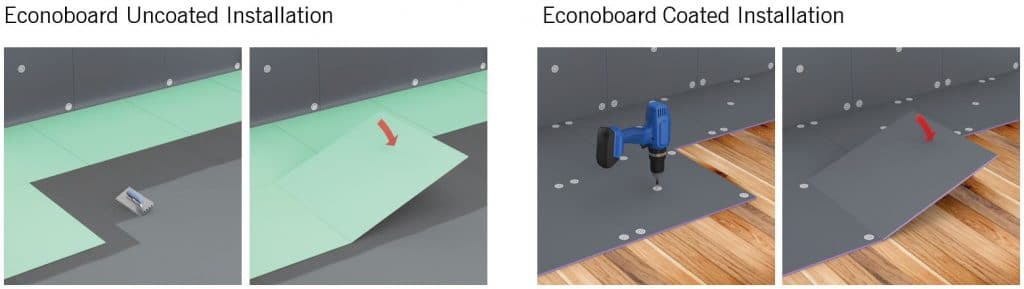

Econoboard Insulation comes in both Coated and Uncoated options. Econoboard Coated board consists of a high-density extruded polystyrene core with a polymer modified fibre reinforced cement coating on both sides whereas the Econoboard Uncoated board are made from a XPS extruded polystyrene foam. Using the correct type of insulation board is vital for the correct floor build-up and optimal performance of your heating system.

So how do you decide whether to use Coated or Uncoated Econoboard?

Coated Econoboard is designed to be used on a timber substrate to add strength and rigidity to the floor build-up, and is also the recommended option in all bathrooms and wet areas so that it can be waterproofed either beneath or on top. Uncoated Econoboard is designed to be used on a solid, stable substrate such as a concrete substrate or cement sheeting; this is not suitable to be screwed down to a timber subfloor or to be waterproofed over.

On a timber substrate, Coated Econoboard is fixed down using Econoboard fixing washers and screws (6022). On a concrete substrate, the Econoboard (either Coated or Uncoated) can be fixed down using a full bed of flexible tile adhesive. Refer to the full installation guides for further information.

Features of Coated Econoboard Insulation Boards

- The ideal solution for insulating a wetroom that is being waterproofed

- Designed for use on a timber or concrete substrate

- Improves the efficiency of underfloor heating by reducing downward heat loss

- Reduces running costs of the underfloor heating by up to 50%

- Available is both 6mm or 10mm thickness

- Can be installed on floor and walls

- 100% moisture resistant and rot proof

- Fixed to timber substrate with Econoboard fixing washers and screws (6022), or fixed to a concrete substrate using a bed of flexible tile adhesive

- Provides lateral and flexural stability of timber floors

Features of Uncoated Econoboard Insulation Boards

- Designed for use on a stable substrate e.g. concrete substrate

- Improves the efficiency of underfloor heating by reducing downward heat loss

- Reduces running costs of the underfloor heating by up to 50%

- Available is both 6mm or 10mm thickness

- Cheaper to purchase and comes in larger pack sizes than Coated boards, making it ideal for large living areas

- 100% moisture resistant and rot proof

- Installed on concrete substrate with a bed of flexible tile adhesive

- Lightweight and easy to work with

- Maximum Insulation with minimum height build-up